Introduction

Practice Occupational Health and Safety Procedures

Learning Outcomes:

At the end of this Lesson, you are expected to do the following:

- LO 1. Identify hazards and risks.

- LO 2. Evaluate and control hazards and risks.

Occupational health and safety (OHS) focuses on primary prevention of hazards while dealing with employees at the workplace. The risk factors at the workplace and several determinants of health of the workers account for accidents, musculoskeletal and respiratory diseases, cancers, hearing loss, circulatory and communicable diseases, stress related disorders and others. Occupational health and safety (OHS) relates to safety, health and welfare issues at workplace. OHS includes standards, laws and programs aimed at improving workplace conditions for workers and co-workers, family members, customers and other stakeholders. Improving occupational health and safety standards ensure better brand image, good business and higher employee morale. Occupational health and safety address different types of workplace hazards and concerns such as chemicals and physical hazards, biological agents, psychological fallout, ergonomic issues and accident Working with electricity can be dangerous. Engineers, electricians, and other professionals work with electricity directly, including working on overhead lines, cable harnesses, and circuit assemblies. Others, such as office workers and sales people, work with electricity indirectly and may also be exposed to electrical hazards. Electricity has long been recognized as a serious workplace hazard. OSH's electrical standards are designed to protect employees exposed to dangers such as electric shock, electrocution, fires, and explosions. Electricity has long been recognized as a serious workplace hazard. OSH's electrical standards are designed to protect employees exposed to dangers such as electric shock, electrocution, fires, and explosions. The references on this page provide information related to electrical in construction including OSH's electrical construction regulations, hazard recogition, possible solutions and general resources. Many workers are unaware of the potential electrical hazards present in their work environment, which makes them more vulnerable to the danger of electrocution. According to 29 CFR 1926.21(b)(2), "The employer shall instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his work environment to control or eliminate any hazards or other exposure to illness or injury. A variety of possible solutions may be implemented to reduce or eliminate the risk of injury associated with electrical work. Examples of solutions include the use of insulation, guarding, grounding, electrical protective devices, and safe work practices.

Occupational Safety covers the risk factor in your workplace, and potential safety hazards that could possibly cause injury. Occupational Health, on the other hand, looks at potential health concerns and wellbeing. Think of Safety as an employee’s physical well-being, and Health as everything else, including mental health. Whether you’re stacking shelves, studying a PhD, working from an office, or using heavy machinery, there are health and safety risks. That being the case, your employer has a responsibility to minimize those risks and reduce the likelihood of any workplace accident or mistreatment. And, as we’re about to explain, it’s in more than just their legal interest to look after you. OH&S will also create new opportunities in your workplace. Staff that have been trained can take on the responsibility of becoming mental health ambassadors, setting a good example and serving as a point-of-contact for their colleagues.

Task

Electricity has the potential to seriously injure and kill. Electrical hazards are in every electrical powered tool or device; they exist also in contact with exposed live parts, faults which could cause fire or explosions where an electrical fault is the source of ignition. Electrocution incidents can be fatal, while non-fatal shocks can result in serious and permanent burn injuries to skin, internal tissues and damage to the heart depending on the length and severity of the shock. Electric shocks from faulty electrical equipment may also lead to related injuries, including falls from ladders, scaffolding or other elevated work platforms. Other injuries or illnesses may include muscle spasms, palpitations, nausea, vomiting, collapse and unconsciousness. Those working with electricity may not be the only ones at risk. Poor electrical installation and faulty electrical appliances can lead to electric shock to others at or near the workplace.

Electric hazards assessment Consider the following hazards in your risk assessment:

1. Live parts Normal mains voltage, 230 volts AC, can kill. Also, contact with live parts can cause shocks and burns.

2. Fire Electrical faults can cause fires. This is particularly true where the equipment contains a heat source (e.g. heaters, including water heaters, washing machines, ovens, heat-seal packaging equipment).

3. Flammable or explosive atmospheres- Electricity can be a source of ignition in a potentially flammable or explosive atmosphere, e.g. in spray paint booths or around refuelling areas.

4. Where and how electricity is used The risks from electricity are greatest in harsh conditions.

5. In wet conditions, unsuitable equipment can easily become live and can make its surroundings live.

6. While outdoors, equipment may not only become wet but may be at greater risk of damage.

7. In cramped or confined spaces with a lot of earthed metalwork, such as inside tanks, ducts and silos, if an electrical fault develops it can be very difficult to avoid a shock.

8. Types of equipment in use Some items of equipment can also involve greater risk than others. Extension leads are particularly liable to damage to their plugs and sockets, cables, and electrical connections. Other flexible leads, particularly those connected to equipment that is moved a great deal, can suffer from similar problems.

Basic electrical safety

Below are some minimum steps you should take to ensure electrical safety.

1.install new electrical systems to BS 7671 Requirements for Electrical Installations

2.maintain all electrical installations in good working order

3.provide enough socket-outlets for equipment in use -avoid overloading socketoutlets – using adaptors can cause fires

4. provide an accessible and clearly identified switch ('Emergency Off' or 'EMO' button) near fixed machinery to cut off power in an emergency for portable

Electric Risks equipment, connect to nearby socket-outlets so that it can be easily disconnected in an emergency.

Use the right equipment

1.choose electrical equipment that is suitable for its working environment

2.ensure that equipment is safe when supplied and maintain it in a safe condition

3. electrical equipment used in flammable/explosive atmospheres should be designed not to produce sparks. Seek specialist advice when choosing this type of equipment.

4. protect light bulbs and other easily damaged equipment – there is a risk of electric shock if they are broken.

Maintenance and repairs

1. ensure equipment is fitted with the correctly rated fuse.

2.ensure cable ends always have their outer sheaths firmly clamped to stop wires working loose from plugs or inside equipment

3. replace damaged sections of cable completely – never repair cuts with insulating tape.

4.use proper connectors to join lengths of cable – don't use connector blocks covered in insulating tape or 'splice' wires by twisting them together

5. some equipment is double insulated. These are often marked with a ‘doubles quare’ symbol. The supply leads have only two wires – live (brown) and neutral (blue)

6.make sure all wires are connected securely if the 13A plug is not a moulded-on type

Process

Evaluation

Electrical Safety - Basic Information

Why is it so important to work safely with or near electricity?

The voltage of the electricity and the available electrical current in regular businesses and homes has enough power to cause death by electrocution. Even changing a light bulb without unplugging the lamp can be hazardous because coming in contact with the "hot", "energized" or "live" part of the socket could kill a person.

What do I need to know about electricity?

All electrical systems have the potential to cause harm. Electricity can be either "static" or "dynamic." Dynamic electricity is the uniform motion of electrons through a conductor (this is known as electric current). Conductors are materials that allow the movement of electricity through it. Most metals are conductors. The human body is also a conductor. This document is about dynamic electricity.

Note: Static electricity is accumulation of charge on surfaces as a result of contact and friction with another surface. This contact/friction causes an accumulation of electrons on one surface, and a deficiency of electrons on the other surface. The OSH Answers document on How Do I Work Safely - Static Electricity has more information.

Electric current cannot exist without an unbroken path to and from the conductor. Electricity will form a "path" or "loop". When you plug in a device (e.g., a power tool), the electricity takes the easiest path from the plug-in, to the tool, and back to the power source. This is action is also known as creating or completing an electrical circuit.

What kinds of injuries result from electrical currents?

People are injured when they become part of the electrical circuit. Humans are more conductive than the earth (the ground we stand on) which means if there is no other easy path, electricity will try to flow through our bodies.

There are four main types of injuries: electrocution (fatal), electric shock, burns, and falls. These injuries can happen in various ways:

- Direct contact with exposed energized conductors or circuit parts. When electrical current travels through our bodies, it can interfere with the normal electrical signals between the brain and our muscles (e.g., heart may stop beating properly, breathing may stop, or muscles may spasm).

- When the electricity arcs (jumps, or "arcs") from an exposed energized conductor or circuit part (e.g., overhead power lines) through a gas (such as air) to a person who is grounded (that would provide an alternative route to the ground for the electrical current).

- Thermal burns including burns from heat generated by an electric arc, and flame burns from materials that catch on fire from heating or ignition by electrical currents or an electric arc flash. Contact burns from being shocked can burn internal tissues while leaving only very small injuries on the outside of the skin.

- Thermal burns from the heat radiated from an electric arc flash. Ultraviolet (UV) and infrared (IR) light emitted from the arc flash can also cause damage to the eyes.

- An arc blast can include a potential pressure wave released from an arc flash. This wave can cause physical injuries, collapse your lungs, or create noise that can damage hearing.

- Muscle contractions, or a startle reaction, can cause a person to fall from a ladder, scaffold or aerial bucket. The fall can cause serious injuries.

What should I do if I think I am too close to overhead power lines?

Do not work close to power lines. Recommended distances vary by jurisdiction and/or utility companies. Check with both your jurisdiction and electrical utility company when working, driving, parking, or storing materials closer than 15 m (49 feet) to overhead power lines.

- If you must be close to power lines, you must first call your electrical utility company and they will assist you.

- If your vehicle comes into contact with a power line:

- DO NOT get out of your vehicle.

- Call 911 and your local utility service for help.

- Wait for the electrical utility to come and they will tell you when it is safe to get out of your vehicle.

- Never try to rescue another person if you are not trained to do so.

- If you must leave the vehicle (e.g., your vehicle catches on fire), exit by jumping as far as possible – at least 45 to 60 cm (1.5 to 2 feet). Never touch the vehicle or equipment and the ground at the same time. Keep your feet, legs, and arms close to your body.

- Keep your feet together (touching), and move away by shuffling your feet. Never let your feet separate or you may be shocked or electrocuted.

- Shuffle at least 10 metres away from your vehicle before you take a normal step.

- Do not enter an electrical power substation, or other marked areas.

What are some general safety tips for working with or near electricity?

- Inspect portable cord-and-plug connected equipment, extension cords, power bars, and electrical fittings for damage or wear before each use. Repair or replace damaged equipment immediately.

- Always tape extension cords to walls or floors when necessary. Do not use nails and staples because they can damage extension cords and cause fire and shocks.

- Use extension cords or equipment that is rated for the level of amperage or wattage that you are using.

- Always use the correct size fuse. Replacing a fuse with one of a larger size can cause excessive currents in the wiring and possibly start a fire.

- Be aware that unusually warm or hot outlets or cords may be a sign that unsafe wiring conditions exists. Unplug any cords or extension cords from these outlets and do not use until a qualified electrician has checked the wiring.

- Always use ladders made with non-conductive side rails (e.g., fibreglass) when working with or near electricity or power lines.

- Place halogen lights away from combustible materials such as cloths or curtains. Halogen lamps can become very hot and may be a fire hazard.

- Risk of electric shock is greater in areas that are wet or damp. Install Ground Fault Circuit Interrupters (GFCIs) as they will interrupt the electrical circuit before a current sufficient to cause death or serious injury occurs.

- Use a portable in-line Ground Fault Circuit Interrupter (GFCI) if you are not certain that the receptacle you are plugging your extension cord into is GFCI protected.

- Make sure that exposed receptacle boxes are made of non-conductive materials.

- Know where the panel and circuit breakers are located in case of an emergency.

- Label all circuit breakers and fuse boxes clearly. Each switch should be positively identified as to which outlet or appliance it is for.

- Do not use outlets or cords that have exposed wiring.

- Do not use portable cord-and-plug connected power tools if the guards are removed.

- Do not block access to panels and circuit breakers or fuse boxes.

- Do not touch a person or electrical apparatus in the event of an electrical incident. Always disconnect the power source first.

What are some tips for working with power tools?

- Switch all tools OFF before connecting them to a power supply.

- Disconnect and lockout the power supply before completing any maintenance work tasks or making adjustments.

- Ensure tools are properly grounded or double-insulated. The grounded equipment must have an approved 3-wire cord with a 3-prong plug. This plug should be plugged in a properly grounded 3-pole outlet.

- Test all tools for effective grounding with a continuity tester or a Ground Fault Circuit Interrupter (GFCI) before use.

- Do not bypass the on/off switch and operate the tools by connecting and disconnecting the power cord.

- Do not use electrical equipment in wet conditions or damp locations unless the equipment is connected to a GFCI.

- Do not clean tools with flammable or toxic solvents.

- Do not operate tools in an area containing explosive vapours or gases, unless they are intrinsically safe and only if you follow the manufacturer's guidelines.

What are some tips for working with power cords?

- Keep power cords clear of tools during use.

- Suspend extension cords temporarily during use over aisles or work areas to eliminate stumbling or tripping hazards.

- Replace open front plugs with dead front plugs. Dead front plugs are sealed and present less danger of shock or short circuit.

- Do not use light duty extension cords in a non-residential situation.

- Do not carry or lift up electrical equipment by the power cord.

- Do not tie cords in tight knots. Knots can cause short circuits and shocks. Loop the cords or use a twist lock plug.

What is a Ground Fault Circuit Interrupter (GFCI)?

A Class A Ground Fault Circuit Interrupter (GFCI) works by detecting any loss of electrical current in a circuit (e.g., it will trip at a maximum of 6mA). When a loss is detected, the GFCI turns the electricity off before severe injuries or electrocution can occur. A painful non-fatal shock may occur during the time that it takes for the GFCI to cut off the electricity so it is important to use the GFCI as an extra protective measure rather than a replacement for safe work practices.

GFCI wall outlets can be installed in place of standard outlets to protect against electrocution for just that outlet, or a series of outlets in the same branch circuit. A GFCI Circuit Breaker can be installed on some circuit breaker electrical panels to protect an entire branch circuit. Portable in-line plug-in GFCIs can be plugged into wall outlets where appliances will be used.

When and how do I test the Ground Fault Circuit Interrupter (GFCI)?

It is important that you follow the manufacturer's instructions with respect to the use of a GFCI. Test permanently wired GFCIs monthly, and portable devices before each use. Use a GFCI tester. You may also test by pressing the "test" and "reset" buttons. Plug a "night light" or lamp into the GFCI-protected wall outlet (the light should turn on), then press the "TEST" button on the GFCI. If the GFCI is working properly, the light should go out. If not, have the GFCI repaired or replaced. Press the "RESET" button on the GFCI to restore power.

Contact a qualified electrician if you are unsure or to correct any wiring errors.

What is a sample checklist for basic electrical safety?

Inspect Cords and Plugs

- Check extension cords and plugs daily. Do not use, and discard cords and plugs if they are worn or damaged.

- Have any extension cord that feels more than comfortably warm checked by an electrician.

Eliminate Octopus Connections

- Do not plug several items into one outlet.

- Pull the plug, not the cord.

- Do not disconnect power supply by pulling or jerking the cord from the outlet. Pulling the cord causes wear and may cause a shock.

Never Break OFF the Third Prong on a Plug

- Replace broken 3-prong plugs and make sure the third prong is properly grounded.

Never Use Extension Cords as Permanent Wiring

- Use extension cords only to temporarily supply power to an area that does not have a power outlet.

- Keep extension cords away from heat, water and oil. They can damage the insulation and cause a shock.

- Do not allow vehicles to pass over unprotected extension cords. Extension cords should be put in protective wireway, conduit, pipe or protected by placing planks alongside them.

Conclusion

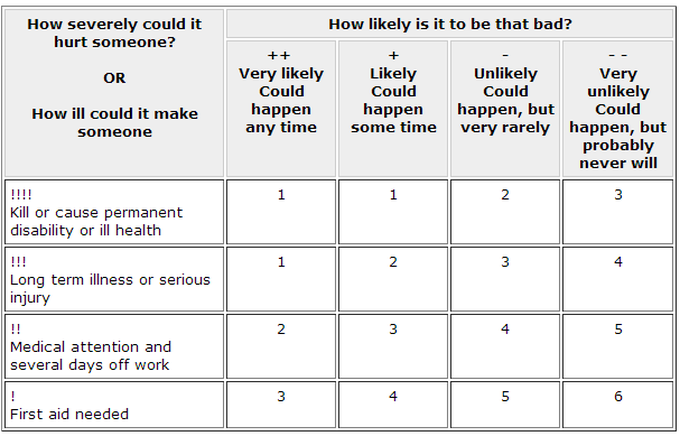

Occupational safety and health is an area concerned with protecting the safety, health and welfare of people engaged in work or employment. The goals of occupational safety and health programs include fostering a safe and healthy work environment. This study was to assess the existing situation of occupational health and safety in the textile industries of Lahore. The study also focused to analyze the health and safety related issues in the industries along with their risk assessment and to evaluate work related diseases which affects the health of labors. Health, safety and risk analysis were carried out in large scale textile industries of Lahore. To carry out this assessment survey was conducted from workers in both industries. The questionnaire was based on working time, number of accidents, cause of accident, affected part of body, nature of injury, use of personal protection equipment's(PPE), health safety policy, first aid facility and risk analysis was based on severity and likelihood of workers. Results showed that the mostly noise level, illumination level, humidity level, and stack emission values were within the NEQS and OSHA values. Pearson's chi-square showed the significance (p = 0.05) relation between affected part of respondent and working section, nature of injury and working section. The overall health safety policy was not well applied and mostly workers were unaware about PPE.